Shielding Gases

Shielding Gases

Shielding gases are inert or semi inert gases that are commonly used in several welding processes, most notably gas metal arc welding and gas tungsten arc welding (GMAW and GTAW, more popularly known as MIG and TIG, respectively). Their purpose is to protect the weld area from atmospheric gases, such as oxygen, nitrogen, carbon dioxide, and water vapour. Depending on the materials being welded, these atmospheric gases can reduce the quality of the weld or make the welding process more difficult to use. Improper choice of a welding gas can lead to a porous and weak weld, or to excessive spatter, the latter, while not affecting the weld itself, causes loss of productivity due to the manpower needed to remove the scattered drops.

Properties

The important properties of shielding gases are their thermal conductivity and heat transfer properties, their density relative to air, and how easy they undergo ionization. Gases heavier than air (e.g. argon) blanket the weld and require lower flow rates than gases lighter than air (e.g. helium). Heat transfer is important for heating the weld around the arc. Ionizability influences how easy the arc starts and how high voltage is required. Shielding gases can be used pure, or as a blend of two or three gases.

The thermal conductivity influences weld forming, weld-pool temperature, degassing and welding speed. For example, the welding speed and penetration can be markedly increased by the addition of helium in the MIG and TIG welding of aluminium materials, or by the addition of hydrogen in the TIG welding of stainless steels.

Chemical properties influence the metallurgical behaviour as well as the weld surface qualities. Oxygen for example, burns off alloy constituents and leads to more fluid weld pools, while carbon dioxide adds carbon and gives slightly reinforced welds. Argon and helium show metallurgically neutral behaviour and hydrogen acts as a reducing agent.

Contact your local BJ Howes or Metaland branch for further information and advice. BJ Howes and Metaland supply a wide range of shielding gases for all applications, and can provide solutions, both cost effective and technical for all your applications. We supply some of the highest capacity options in Australia, thereby helping to reduce unit costs, changeover times and labour costs. We also offer potential rental cost reductions.

Further information:

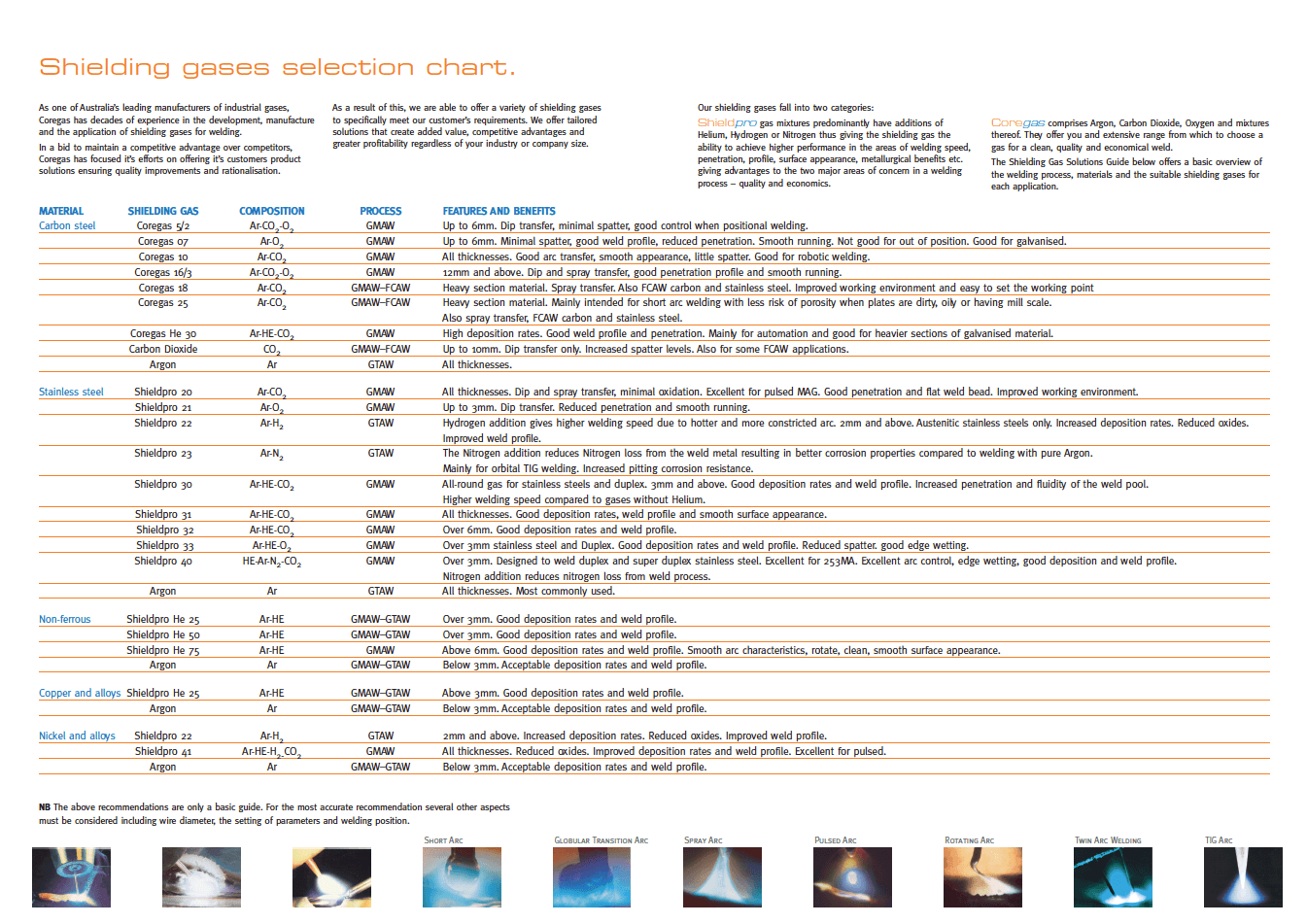

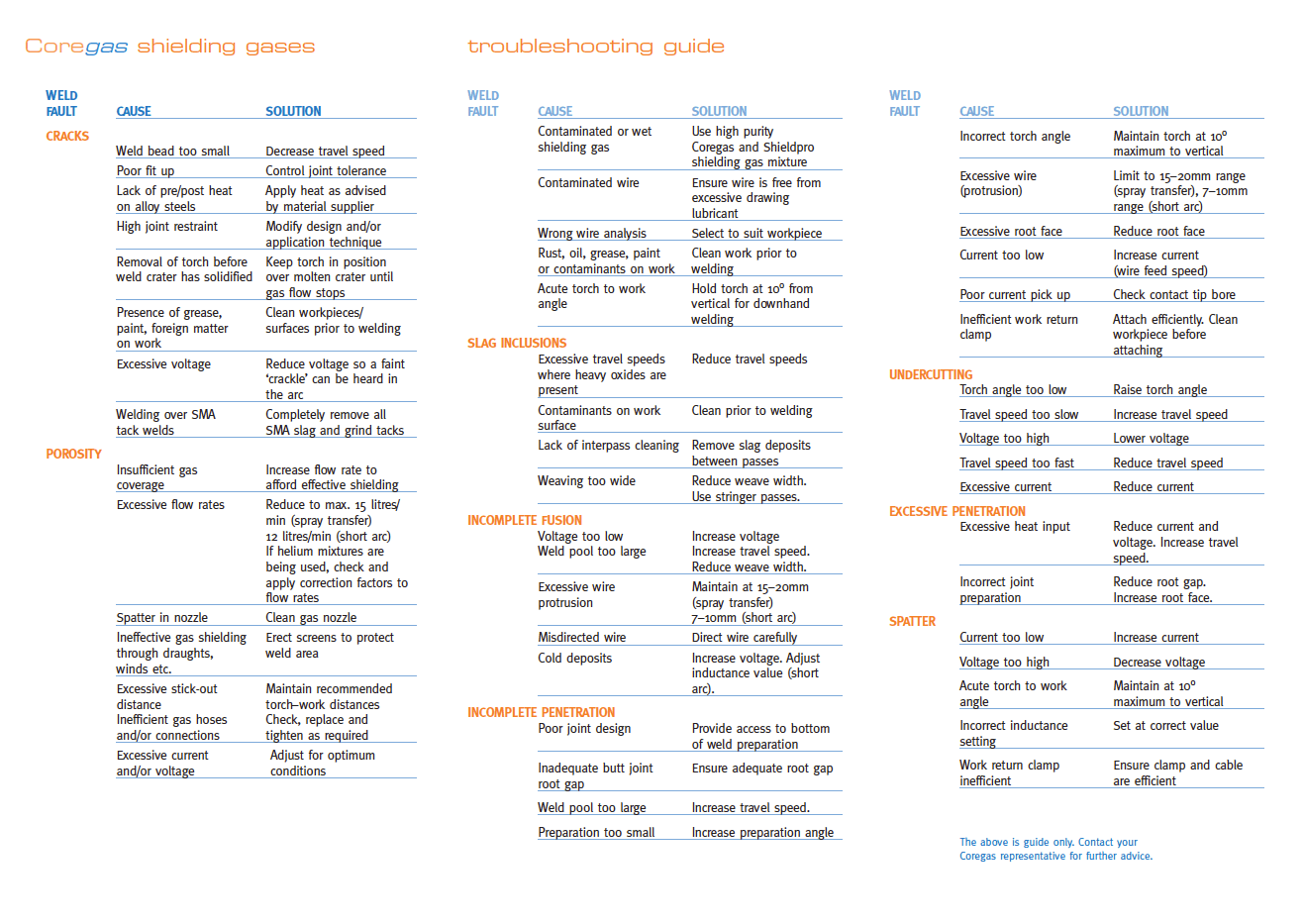

The following are guides for choosing the right shielding gas for your specific application or troubleshooting if encountering welding faults.

View the full range of our industrial, hospitality and medical gases below:

Fuel Gases

Laser Gases

Hospitality Gases

Medical Gases

Trade’N’Go Gas